Business

Morison gearing to re-shape pharmaceutical industry in SL by 2030

Sri Lanka’s pharma industry with 1959-roots still producing only 15% of national requirement

Locally manufactured drugs have only 5% market share in private pharma market

Morison to compete with foreign brands with the commencement of commercial manufacturing

by Sanath Nanayakkare

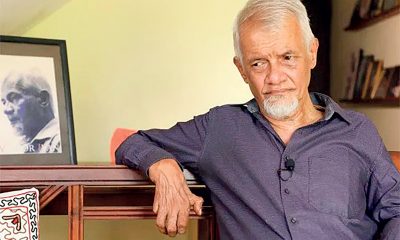

It may be a long journey ahead, but we are going to accomplish it with the support of our science-driven, passionate, young team employed at our pharmaceutical manufacturing plant in Homagama, Dinesh Athapaththu, MD at Morison PLC told the media recently.

He said so while addressing a media roundtable at the LKR 4 billion worth state-of-the-art pharmaceutical manufacturing plant operating with minimum human involvement and maximum automation.

“We have embarked on a journey upstream of changing the landscape of the pharma manufacturing industry in Sri Lanka in order to make premium healthcare affordable for everyone,” he said.

“Healthcare is in the news for all the wrong reasons. Some Sri Lankan companies like Morison are trying to take the pharmaceutical industry to the next level after decades of stagnation. However, it is not receiving positive media attention, and therefore, the general public of the country as well as many doctors don’t know what Morison is doing to make this crucial investment work for Sri Lanka.

It has been more than three years since we made this investment and most of our resources still go into product development. Sri Lanka commenced pharmaceutical manufacturing in 1959, but it is still manufacturing just 15% of the national requirement whereas our neigbouring countries are far ahead of us in national supply volumes and export volumes.

“India, Pakistan, Bangladesh and Sri Lanka commenced pharma manufacturing in the 1950s which means pharma manufacturing in these countries got off the ground around the same time in history. In Sri Lanka, that feat was achieved by J.L Morison Son & Jones (Ceylon) PLC. Their facility at Aluth Mawatha, Mutwal became one of the pioneers of generic pharmaceutical manufacturing in Sri Lanka. However, 65 years on, Sri Lanka is still producing only 15% of its national medicine requirement whereas India is self-sufficient plus USD 20 billion worth exports, Bangladesh 95% self-sufficient plus exports worth USD 3 billion, Pakistan 70% self-sufficient plus exports worth USD 5 billion.

“Sri Lanka’s total pharmaceutical market is estimated at about USD 600 million where 40% of that drugs value is dispensed through government hospitals while 60% is dispensed by private pharmacies. Only 25% of the total 15% locally manufactured pharmaceuticals are dispensed by the government. Most local manufacturers focus on supplying this 25% requirement to the government.

On the other hand, in the private market where doctor-prescribed brands are sold, the locally manufactured products have only a 5% market share, meaning 95% of the products sold in the private market are imported drugs. Having studied this, Morison decided to try and change things around even at this late stage by becoming a manufacturer of branded drugs of international standards in addition to being a bulk generic supplier to the government.”

“Before we built the new plant in Homagama, we went to India and Pakistan to see the pharmaceutical plants there. We realized that we have an issue with the absence of high quality plants in Sri Lanka to go out and promote our products among doctors and private pharmacies. It was evident that we needed to bring high quality pharma manufacturing standards into the country in order to be able to manufacture drugs of the highest quality, safety and efficacy standards such as EU GMP. So we made a bold investment of LKR 4 billion to build this plant. We have been running the plant in compliance with WHO GMP (Good Manufacturing Practice) and EU GMP standards.”

‘Morison decided to take a long term view of this industry and enter the private market, without solely depending on government supplies which could be subject to policy changes from time to time. Therefore, our committed mission now is building a credible pharmaceutical brand which can readily compete with reputed imported pharma brands built on a patient-centric approach.”

“Indian pharma is in a good position today after about 60 -65 years’ of dedication. In Sri Lanka, proper pharmaceutical manufacturing has not significantly evolved. So we have to make necessary changes to transform this industry. For that, primarily we need to take a long term view of sustainable growth and subsequently about the return on investment. Our shareholders are being patient and supportive of our strategy.

We need to attract a lot of qualified young people into the industry to come and work because they will grow with the industry as we are gearing to make a notable impact in the pharmaceutical industry in Sri Lanka. be the best pharma brand in Sri Lanka by 2030, and effectively compete with foreign brands. At our Homagama factory, the average age of our workforce is around 30 years. The beauty of that is; in ten years, the most qualified Sri Lankan pharmaceutical manufacturing personnel will be around 40-years old,” a confident Dinesh said.

J.L. Morison Son & Jones (Ceylon) PLC was acquired by Hemas Holdings PLC in 2013, and today it is re-branded as Morison, retaining a sense of that historical legacy.

Morison’s Homagama manufacturing facility at present manufactures five drugs and has developed about 26 drugs out of which 10- 12 are in NMRA for registration and the rest are to be submitted for registration.

Morison is planning to submit for accreditation for their Homagama facility once it fulfills the complex European procedures, after which Morison’s products will have easier access to lucrative foreign markets, thereby earning much needed foreign currency for Sri Lanka.

Business

LankaPay Technnovation Awards to spotlight inclusive FinTech as digital payments expand across Sri Lanka

Sri Lanka’s digital payments revolution is gathering unprecedented momentum, with more than 260 government institutions now integrated into the national digital payments ecosystem, marking a decisive shift toward financial transparency, efficiency and inclusion, officials said at a press briefing held at the Hilton Colombo Residences.

The announcement coincided with the launch of the eighth edition of the LankaPay Technnovation Awards 2026 by LankaPay, Sri Lanka’s national payment network, under the theme “Inclusive FinTech,” recognising financial institutions, fintech companies and government entities that have expanded access to secure and convenient digital financial services across the country.

Chief Executive Officer of LankaPay, Channa de Silva, said the rapid expansion of digital payment adoption reflects a structural transformation in Sri Lanka’s financial architecture.

“The growth we are witnessing in digital payments is not merely technological progress—it represents a fundamental shift in how financial services are delivered and accessed. Our national payment infrastructure is enabling real-time, secure and inclusive transactions that empower individuals, businesses and government institutions,” de Silva said.

He said LankaPay’s continued investment in interoperable and accessible payment infrastructure is helping bring more citizens into the formal financial system while strengthening economic governance.

“Our objective is to ensure digital payments are accessible to all Sri Lankans, from urban centres to the most remote communities. Inclusive digital finance strengthens economic participation and supports sustainable national development,” he said.

Officials said the onboarding of 260 government institutions within a year represents a remarkable leap from just eight institutions previously connected, underscoring the State’s accelerating digital transformation agenda.

“This expansion required extensive engagement across the country. Our teams worked directly with government departments, municipal councils and regional authorities to ensure successful integration into the digital payments ecosystem,”

LankaPay officials said, noting that institutions from regions including Kurunegala, Jaffna and Trincomalee had recently been onboarded.

Authorities said the digital integration of government services improves transparency, reduces administrative inefficiencies and enhances public convenience, while enabling better financial oversight and accountability.

The LankaPay Technnovation Awards, first introduced in 2017, have become Sri Lanka’s benchmark platform recognising excellence and innovation in payment technology, honouring institutions that have demonstrated leadership in advancing digital payments and financial inclusion.

The grand awards ceremony is scheduled to be held on March 24 at the Cinnamon Life under the patronage of Nandalal Weerasinghe, Governor of the Central Bank of Sri Lanka, as Chief Guest. Eranga Weerarathne, Deputy Minister of Digital Economy, and Hans Wijayasuriya, Chief Advisor to the President on Digital Economy, will attend as Guests of Honour.

Officials said the awards recognise outstanding achievements across multiple categories, including financial inclusivity, customer convenience, digital government payments and cross-border payment enablement, reflecting the breadth of innovation taking place within Sri Lanka’s financial services sector.

By Ifham Nizam

Business

HNB supports Sri Lanka’s recovery with record advances growth

HNB Group delivered strong performance in 2025, with Group Profit After Tax (PAT) reaching Rs 49.8 Bn, reflecting the continued progress. The Bank’s PAT stood at Rs 45.4 Bn, supported by robust balance sheet expansion and sustained improvements in asset quality.

Commenting on the performance, Nihal Jayawardena, Chairman of HNB PLC, stated,”The year 2025 marked a decisive shift in Sri Lanka’s economic trajectory, supported by improving macroeconomic fundamentals, renewed private sector confidence, and continued progress in national reform efforts. HNB’s strong balance sheet expansion, disciplined risk management, and sustained investment in digital and operational capabilities position the Bank to play an essential role in supporting the country’s revival”.

“While the year concluded with the severe impact of Cyclone Ditwah, the resilience demonstrated by communities and institutions underscored the importance of a banking sector that remains agile, responsive, and deeply committed to national progress. We will continue to work closely with stakeholders to mobilise capital, rebuild affected livelihoods, and strengthen long‑term economic stability.”

Despite strong credit growth, net interest margins remained under pressure amid an accommodative monetary policy stance. Net Interest Income declined marginally by 0.6% year‑on‑year, reflecting the broad reduction in market interest rates, and the recognition of a portion of overdue interest from the restructuring of Sri Lanka Sovereign Bonds (SLSBs) in December 2024, which temporarily boosted interest income in the previous year. However, the decrease in net interest income was moderated by the increase in interest income from loans and advances, supported by the expansion in the loan book, and the growth in CASA deposits.

Non-fund-based income provided a strong counterbalance, with Net Fee and Commission Income increasing by 28.9% year-on-year on the back of higher card usage and a sharp increase in digital transactions. The significant increase in the demand for trade related services on the back of the reopening of vehicle imports and improving trade activity, saw trade finance emerge as one of the key contributors to non-fund income in the current year. Furthermore, Exchange income rose to Rs 6.3 Bn during the year, reversing the loss of Rs 2.9 Bn recorded in 2024.

Prudent risk management, disciplined underwriting and focused recovery efforts supported a significant improvement in asset quality during the year. The Stage 3 portfolio recorded a net reduction alongside an impairment reversal of Rs 9.2 Bn, following the recognition of Rs 2.2 Bn in post‑model adjustments made prudently for loan exposures with potential vulnerability arising from Cyclone Ditwah.

Business

HNB Assurance delivers industry leading 42% revenue (GWP) growth and 28% rise in profits (PAT)

HNB Assurance PLC reported an outstanding financial performance for the year ended 31st December 2025, delivering a 42% year-on-year growth in Life Insurance Gross Written Premium (GWP), this along with the growth rate in Renewals are the highest in the industry.

Life GWP reached Rs. 19.49 Bn compared to Rs. 13.71 Bn in 2024, reflecting strong New Business generation and Renewal Collection. Net Written Premium grew even faster at 43% to Rs. 18.44 Bn, highlighting the quality and sustainability of the Company’s topline expansion.

Commenting on the results, Chairman Stuart Chapman stated, “The year under review was marked by gradual macroeconomic stabilisation, improved investor sentiment and a more predictable policy environment. Although the economy continues to recover from prior volatility, we are beginning to see renewed financial confidence among individuals and businesses. Against this backdrop, HNB Assurance has delivered strong growth in both revenue and profits, while maintaining robust capital adequacy and prudent risk management. Our improvement in top line, profitability and balance sheet strength demonstrates the resilience of our business model and our ability to navigate changing economic conditions which are reflected in an ROE which increased to 18.5% from 16.9% a year earlier.”

Profit Before Tax increased by 28% to Rs. 3.03 Bn from Rs. 2.36 Bn in the previous year, while Profit After Tax (including Life Surplus Transfer) rose by 28% to Rs. 2.12 Bn compared to Rs. 1.66 Bn in 2024. Earnings Per Share improved by 28% to Rs. 14.15 from Rs. 11.04, reinforcing the Company’s ability to consistently translate business growth into enhanced shareholder value. In line with this strong performance, the Board of Directors has proposed a first and final dividend of Rs. 5.00 per share for 2025, representing a 28% increase over the Rs. 3.90 per share declared in the previous year.

-

Features6 days ago

Features6 days agoWhy does the state threaten Its people with yet another anti-terror law?

-

Features6 days ago

Features6 days agoReconciliation, Mood of the Nation and the NPP Government

-

Features6 days ago

Features6 days agoVictor Melder turns 90: Railwayman and bibliophile extraordinary

-

Features5 days ago

Features5 days agoLOVEABLE BUT LETHAL: When four-legged stars remind us of a silent killer

-

Features6 days ago

Features6 days agoVictor, the Friend of the Foreign Press

-

Latest News7 days ago

Latest News7 days agoNew Zealand meet familiar opponents Pakistan at spin-friendly Premadasa

-

Latest News7 days ago

Latest News7 days agoTariffs ruling is major blow to Trump’s second-term agenda

-

Business5 days ago

Business5 days agoSeeing is believing – the silent scale behind SriLankan’s ground operation